Crafting Modern Mobility Solutions

The growing demand for home elevators reflects a trend towards greater accessibility, convenience, and luxury in residential spaces. Behind every home elevator is a sophisticated manufacturing process that takes place in specialized factories dedicated to producing these intricate systems. This article offers an inside look at how home elevators are designed, built, and tested in a factory setting, highlighting the precision and innovation involved in bringing these essential products to life.home elevator factory

The Manufacturing Process: From Concept to Completion

- Design and Engineering

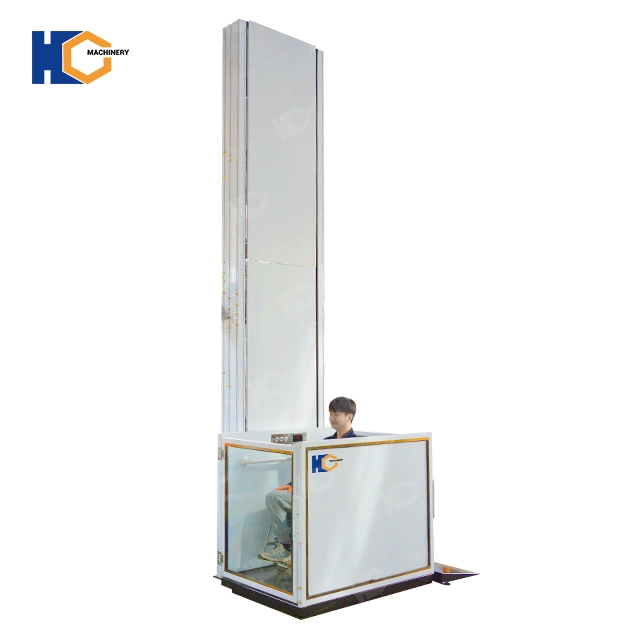

- Initial Design Phase: The journey of a home elevator begins with the design and engineering phase. Engineers and designers work closely to create models that meet various residential needs, whether it’s a compact lift for a small home or a more luxurious and spacious model for a high-end property.

- Customization Options: Factories often provide extensive customization options, allowing customers to choose the aesthetics, materials, and functionalities that best suit their homes. This might include selecting cabin finishes, control panel designs, and door types.

- Technical Specifications: The design phase also involves detailed technical planning. Engineers calculate load capacities, design safety features, and integrate the latest technologies to ensure the elevator operates smoothly and safely.

- Material Selection and Procurement

- High-Quality Materials: The choice of materials is critical in elevator manufacturing. Factories source durable and high-quality materials such as stainless steel, glass, aluminum, and various composites to ensure longevity and reliability.

- Sustainable Sourcing: Many factories are now focusing on sustainability, selecting eco-friendly materials and ensuring that their procurement processes minimize environmental impact.

- Precision Manufacturing

- Component Fabrication: In the factory, various components of the elevator are fabricated using advanced machinery. This includes everything from the elevator car itself to the rails, pulleys, and control systems. Each part is manufactured with precision to meet strict quality and safety standards.

- Assembly Line Efficiency: The assembly process in a home elevator factory is a blend of automation and skilled craftsmanship. Automated systems handle repetitive tasks with precision, while skilled workers oversee more complex assembly stages to ensure accuracy.

- Quality Control and Testing

- Comprehensive Testing: Quality control is a critical aspect of elevator manufacturing. Each elevator undergoes rigorous testing to ensure it meets all safety and operational standards. This includes testing mechanical systems, electrical components, and safety features under various conditions.

- Safety Certifications: Factories must ensure that their products comply with national and international safety standards. Elevators are tested for emergency scenarios, such as power failures or overloading, to ensure they operate safely in all situations.

- Customization and Final Assembly

- Tailored Finishing: After the primary components are assembled and tested, the elevator is customized according to the client’s specifications. This can include installing specific interior finishes, custom lighting, and unique control interfaces.

- Final Checks: Before the elevator leaves the factory, it undergoes a final round of checks to ensure everything functions correctly and meets the design specifications. This final inspection is crucial for maintaining the factory’s reputation for quality and reliability.

- Packaging and Distribution

- Secure Packaging: Once the elevator passes all inspections, it is carefully packaged to prevent damage during transportation. Special attention is given to fragile components, which are securely packed and cushioned.

- Global Logistics: Many home elevator factories distribute their products globally, requiring a well-organized logistics system. Elevators are shipped to homes around the world, ready for installation by specialized technicians.

Innovation in Home Elevator Manufacturing

- Advanced Technology Integration

- Smart Elevators: Modern home elevators often incorporate smart technology, such as touchscreens, remote monitoring, and voice control. Factories are at the forefront of integrating these technologies, offering elevators that are not only functional but also intuitive to use.

- Energy Efficiency: Innovation also extends to energy efficiency. Factories are developing elevators with energy-saving features, such as regenerative drives and LED lighting, which reduce the environmental footprint and operating costs.

- Customization and Design Flexibility

- Modular Systems: To accommodate a variety of home designs and layouts, many factories offer modular elevator systems. These systems can be easily customized and configured, making installation simpler and more adaptable to different spaces.

- Luxury Features: For high-end markets, factories provide luxury enhancements such as panoramic glass cabins, custom wood or metal finishes, and advanced sound systems, catering to customers who seek a blend of technology and opulence.

- Safety Innovations

- Cutting-Edge Safety Features: Safety is a top priority in home elevator manufacturing. Factories are continually innovating to include advanced safety features such as automatic braking systems, emergency communication devices, and backup power supplies.

- Regulatory Compliance: To ensure global usability, factories adhere to strict safety standards and certifications. This compliance is crucial for ensuring the elevators can be installed in various countries, each with its own regulatory requirements.

Conclusion: The Heart of Modern Mobility

A home elevator factory is more than just a production facility—it’s a hub of innovation, quality control, and craftsmanship. From the initial design concept to the final product, every step in the manufacturing process is carefully managed to produce elevators that are safe, reliable, and tailored to the needs of homeowners. As the demand for home elevators grows, these factories continue to push the boundaries of what’s possible, blending cutting-edge technology with meticulous attention to detail. The result is a product that not only enhances the functionality of a home but also adds a touch of luxury and convenience to everyday living.